PVB Resin

Now PB resin could be divided into two kinds according to the relative molecular weight, i.e. high viscosity type and low viscosity type, in which high viscosity PVB resin is mainly used in the laminated safety glass.

Besides, sometimes PVB resin exists in the form of polymer solution, which is widely used for coatings, adhesives, ceramic color film, vacuum aluminum foil, electrical materials, glass steel products, fabric treatment agent, engineering plastics and other fields; and it is a kind of synthetic resin material with a broad prospect for application.

Product Brief description

PVB interlayer film uses 100% pure resin as raw material.

The safety glass pure resin PB film has superior optical properties, high light transmittance and low haze, which makes the glass more transparent. If the laminated glass is made by multilayer pure PB film, the advantages are more obvious.

Secondly, our pure PB interlayer film has a low yellowing index and a high whiteness, so itis particularly suitable for ultra-white laminated glass. PB has excellent environmental performance. Under different environmental conditions, it will not cause degumming, bubble and aging after long time use.

PB interlayer film is mainly used in laminated glass. Laminated glass is a special glass which is inserted with PVB film between two layers of common glass, under high heating temperature and pressure, binding to create a single construction. PB laminated glass with its strength in safety, heat preservation, noise proof, and ultraviolet resistance etc, is widely used in areas such as high buildings, automobile and photovoltaic. Our PB film produced with special formula is also used in aeroplane, space flight ware, military instrument, solar battery, solar energy acceptor and so on.

Advanced Production Process

Extruder is the critical machinery in the whole production, mainly used to mix PVB resins, plasticiser and other reagents by heat. During production heat control is most important. As our extruder is imported from a German famous supplier and is fully automatic, our PVB film’s stability could be ensured.

Glass Mechanical Testing

- 2260 g anti-penetration test

- Head model test

- Shot bag-test

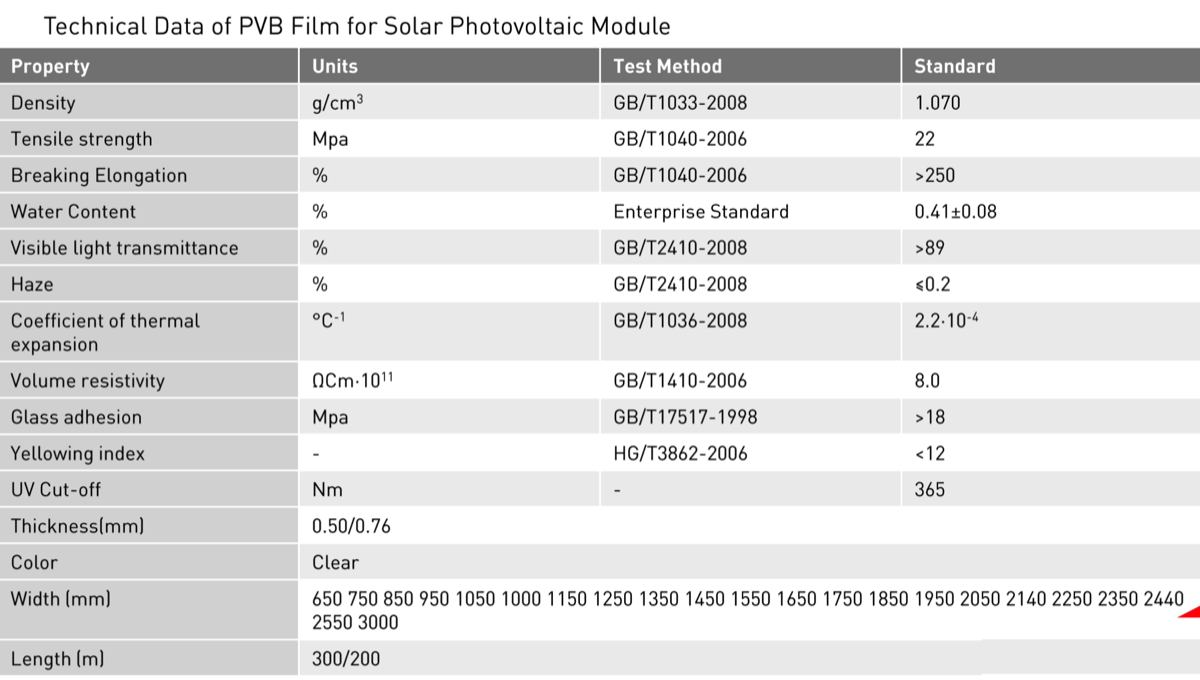

Solar Photovoltaic PVB Film

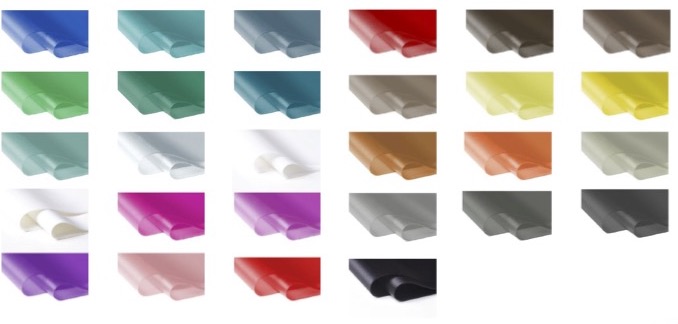

Color PVB Film

Packing & Transportation